SOLVING ELECTRONICS INDUSTRY PROBLEMS

AI-powered quality control & supply chain efficiency

"Driving Innovation & Connectivity"

The electronics industry powers the modern world, from consumer gadgets to industrial systems. It thrives on innovation, delivering cutting-edge technologies in semiconductors, communication devices, and smart electronics. While growth is rapid, the sector faces challenges such as supply chain disruptions, short product lifecycles, rising production costs, and strict regulatory compliance. Companies must balance innovation, quality, and sustainability to stay competitive in this fast-paced, ever-evolving market.

Key Challenges

Logistic & supply chain complexity

Quality Control & Reliability

Equipment downtime & maintenance cost

The Solution

Comprehensive approaches tailored to your industry's specific needs.

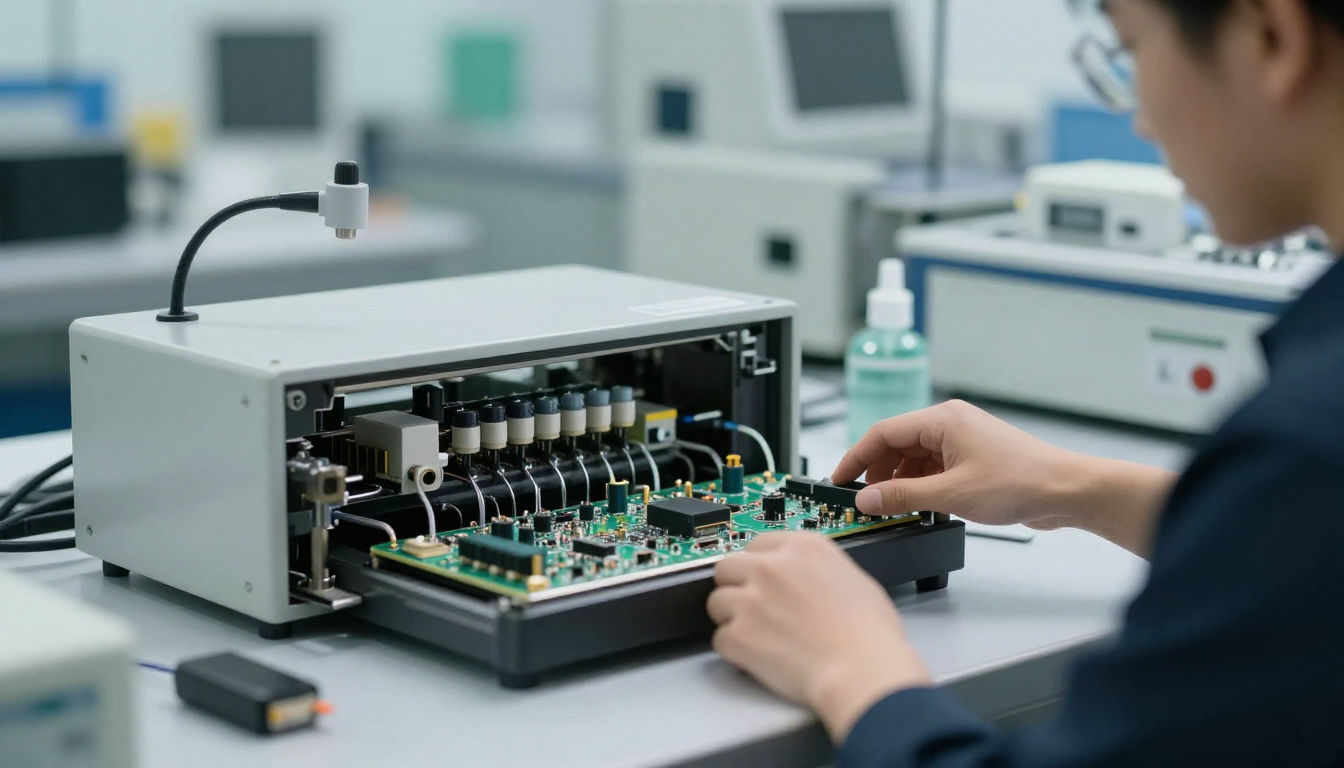

Defect Detection

AI-driven defect detection transforms quality control by identifying microscopic flaws that human inspection often misses. Using high-resolution imaging and machine-learning algorithms, the system evaluates soldering quality, micro-component placement, PCB patterns, and assembly uniformity in real time. This reduces false positives, prevents faulty units from reaching customers, and minimizes warranty claims. Automated defect detection also enhances production line consistency, supports zero-defect manufacturing, and ensures that every product meets high global quality standards.

Inventory Optimization

Managing inventory in the electronics industry is challenging due to component shortages, fluctuating demand, and long supplier lead times. Intelligent inventory optimization uses predictive analytics to track stock movement, anticipate consumption rates, and align orders with production plans. This prevents overstocking high-value components and eliminates costly last-minute procurement. By maintaining the right balance of materials, electronics manufacturers achieve smoother production flow, improved liquidity, and significant cost savings across the supply chain.

Supply Chain Efficiency

A resilient supply chain is essential in electronics manufacturing, where components come from multiple global sources. Real-time tracking provides complete visibility into shipments, vendor performance, transportation timelines, and customs delays. AI-powered planning adjusts production schedules when deliveries fluctuate, reducing assembly line stoppages. With accurate demand-supply alignment, companies avoid costly downtime, accelerate delivery commitments, and operate with greater agility in a market characterized by rapid technological change.

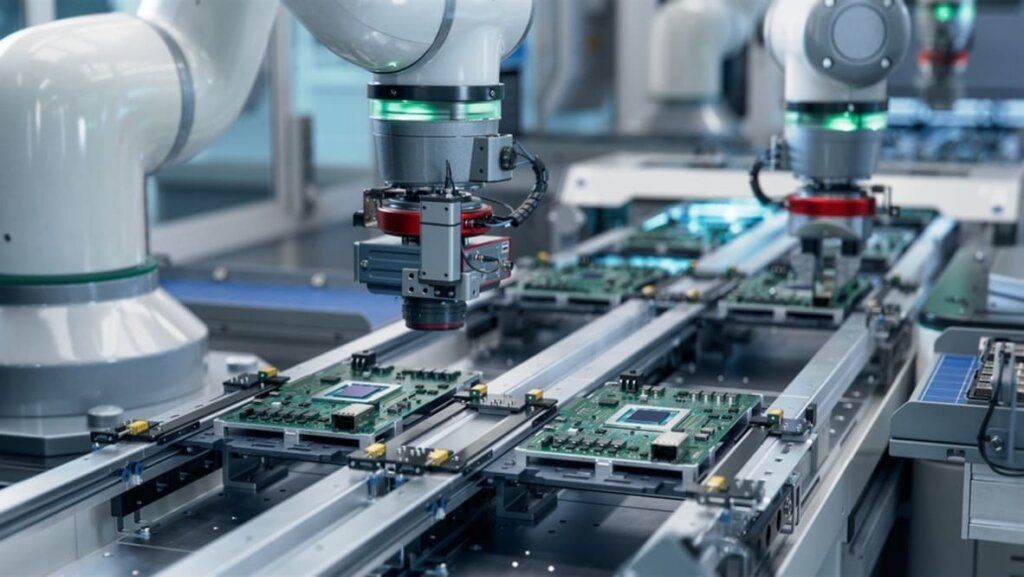

Production Speed

Modern electronics production requires extremely high throughput to meet global demand. Automation streamlines repetitive tasks such as component placement, soldering, inspection, and packaging. With AI-enhanced scheduling and intelligent workflow routing, production lines achieve faster cycle times with fewer human errors. Increased automation not only reduces labor fatigue but also ensures consistent product output, higher line efficiency, and improved capacity to scale production without compromising quality or stability.

Trusted Partners